Onsite SymmeTry Roof Panel Roll Forming

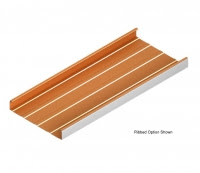

Morin SymmeTry Roof Series- our newest line of roof panels. It is a mechanically seamed structural roof system that is both symmetrical and hydrostatic by design. It has many advantages from easy installation to design features:

- Symmetrical panels that can be installed in any direction, beginning from anywhere

- Mechanically sealed watertight cap

- Vertical legs ranging from 1.5"-3"

- Easy replacement in case of damage

- Can be formed up to 300' at the job site

- Copes with thermal expansion and contraction by sliding over roof clips rather than affixing to them.

- Can be a system to cover existing roofs with insulation in between to increase R-value.

- 3/8" offset of attachment clips saves energy by lowering overall temperature of roof envelope

- System has undergone extensive testing with positive results

Click here to read more about Morin's Symmetry Roofing System.

The SymmeTry Roofing System is the latest roofing system that meets all the requirements of a great roofing system. We have had success with it on many projects all over the country but perhaps the most impressive success story yet has been Logan High school in Russellville, Kentucky.

The SymmeTry Roofing System is the latest roofing system that meets all the requirements of a great roofing system. We have had success with it on many projects all over the country but perhaps the most impressive success story yet has been Logan High school in Russellville, Kentucky.

Logan High School was unlike any other project ever attempted. The project required 18-inchwide Morin SymmeTry Roof Series panel with 2 1/2-inch legs. The 22-gauge Galvalume panels were pre-painted a PVDF Regal White. One side of the roof required 46 feet long panels while the other required panels that were 161 feet, 2 inches in length, too long to ship.

So, a truck transported the coils and roll former from our plant in DeLand, Florida to Kentucky to form the panels on site. We formed about 90,000 square feet of SymmeTry roof panels in the mud and rain. The roll former sat about 100 feet away from the building and angled up towards the roof. We ran a "sacrifice panel" (which was later recycled) to help guide the panels as they were "shot up" onto the roof as they were being formed. Three scissor lifts were placed between the roll former and roof to help guide the panel along. About 11 men were on the roof catching the panels as they arrived and walking them into place.

The shorter panels ran first because they needed to be carried to the other side, then the longer panels were formed. All of the panels were covered with a protective plastic film to be removed immediately after installation to avoid permanent damage to the panel.

So, a truck transported the coils and roll former from our plant in DeLand, Florida to Kentucky to form the panels on site. We formed about 90,000 square feet of SymmeTry roof panels in the mud and rain. The roll former sat about 100 feet away from the building and angled up towards the roof. We ran a "sacrifice panel" (which was later recycled) to help guide the panels as they were "shot up" onto the roof as they were being formed. Three scissor lifts were placed between the roll former and roof to help guide the panel along. About 11 men were on the roof catching the panels as they arrived and walking them into place.

The shorter panels ran first because they needed to be carried to the other side, then the longer panels were formed. All of the panels were covered with a protective plastic film to be removed immediately after installation to avoid permanent damage to the panel.

Everyone onsite from production manager Basil Slagle to the installers agreed that the process was painless, efficient, and innovative.

“The installation went great,” says Nancy Mullins, senior project manager for Eastern Corp. of Norcross, Ga. “We install all the panels and then come back to install the seam cap and do the seaming. We always wait to make sure everything is where it needs to be, in regard to any penetrations. We really had no issues.”

When it comes to roofs, SymmeTry meets the requirements for faster installation and a longer lasting product by having fewer seams and simpler delivery of materials. In addition, running panels on-site is a real time saver for the installer. It offers production panels of any length without lapping them. Because the panels are a single piece, there was no panel-to-panel seaming, and zero chance for leaks.

"A lot of great coordination by Morin made it easier for the installer," says Peter Faulk, marketing manager, Morin. "I saw coordination between so many people facilities and so many new variables. I watched as our expert staff pulled it all together, many details over many weeks. This was a fun success story for the Symmetry Roof Series to share."

“The installation went great,” says Nancy Mullins, senior project manager for Eastern Corp. of Norcross, Ga. “We install all the panels and then come back to install the seam cap and do the seaming. We always wait to make sure everything is where it needs to be, in regard to any penetrations. We really had no issues.”

When it comes to roofs, SymmeTry meets the requirements for faster installation and a longer lasting product by having fewer seams and simpler delivery of materials. In addition, running panels on-site is a real time saver for the installer. It offers production panels of any length without lapping them. Because the panels are a single piece, there was no panel-to-panel seaming, and zero chance for leaks.

"A lot of great coordination by Morin made it easier for the installer," says Peter Faulk, marketing manager, Morin. "I saw coordination between so many people facilities and so many new variables. I watched as our expert staff pulled it all together, many details over many weeks. This was a fun success story for the Symmetry Roof Series to share."

Morin now offers four profiles that can be manufactured onsite. In addition to the SymmeTry Roof Series, Morin has job site machines for the SLR Series roofing profile and curving; SWL Series roofing profile; and MorZip and curving.

Watch the video here!

Learn more:

http://designandbuildwithmetal.com/industry-news/2016/01/15/morin-introduces-new-symmetrical-roof-panel-series

About Morin, A Kingspan Group Company

Morin, a Kingspan Group Company, is one of the industry’s most versatile manufacturers of single element metal wall and roof panel systems. With production facilities in Bristol, CT, Deland, FL and Fontana, CA, MORIN has a combined production capacity of over 50 million square feet, fabricating metal panels in more than 75 different profiles. MORIN Single Element panels are 100 percent recyclable and meet the requirements for the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED®) Green Building Rating System. MORIN’s nationwide sales network and in-house technical service teams are dedicated to providing innovative solutions for today’s progressive architecture. Visit www.morincorp.com to access profiles, specifications, CAD details, load span charts and technical manuals.

I think this may become one of my favourite posts this month. I have bookmarked your website so that I can easily find you and enjoy more useful information.

ReplyDeletemetal siding columbus